Core technology

The Visual System

Picture Perfect Match System

The Picture Perfect Match System, the low cost solution for producing your match mailings, is designed for the mailer who currently hand inserts or hand inspects their match mailings. This PC based system uses cameras magnetically mounted on any swing arm inserter to display the match components on a monitor. Picture Perfect is designed as a low cost alternative to many automatic document vision systems. Picture Perfect also has no limitations on font type, angle, or quality and needs no barcode. It's well suited for the customer that demands the most personalized look. Please note: This is a visual match system. Picture Perfect displays the images on the screen for operator inspection.

- No cams to adjust – timing is done on the monitor.

- Simply press one button and the camera position and timing are set.

- The timing of each camera can be individually adjusted.

- Timing can be readjusted while the machine is running.

- No unplugging and replugging in video cables to move the cameras.

- See all cameras live at the same time and adjust brightness, contrast, etc. individually

- If the camera is upside down to the image, two clicks rotates the picture.

- A matched image is always on the screen, no waiting for the last image to insure the match is still correct.

- Clear color images that have adjustments for each camera for brightness, contrast, sharpness, saturation, hue, and more.

- View a history of the last 10 images to locate a mismatch.

- Cameras zoom in to get a larger image.

- Option to view every piece.

- Set images to update from 1 to 20 cycles regardless of distance between cameras

- No flimsy cable connection.

- Connections are via USB so power and video are via one cable.

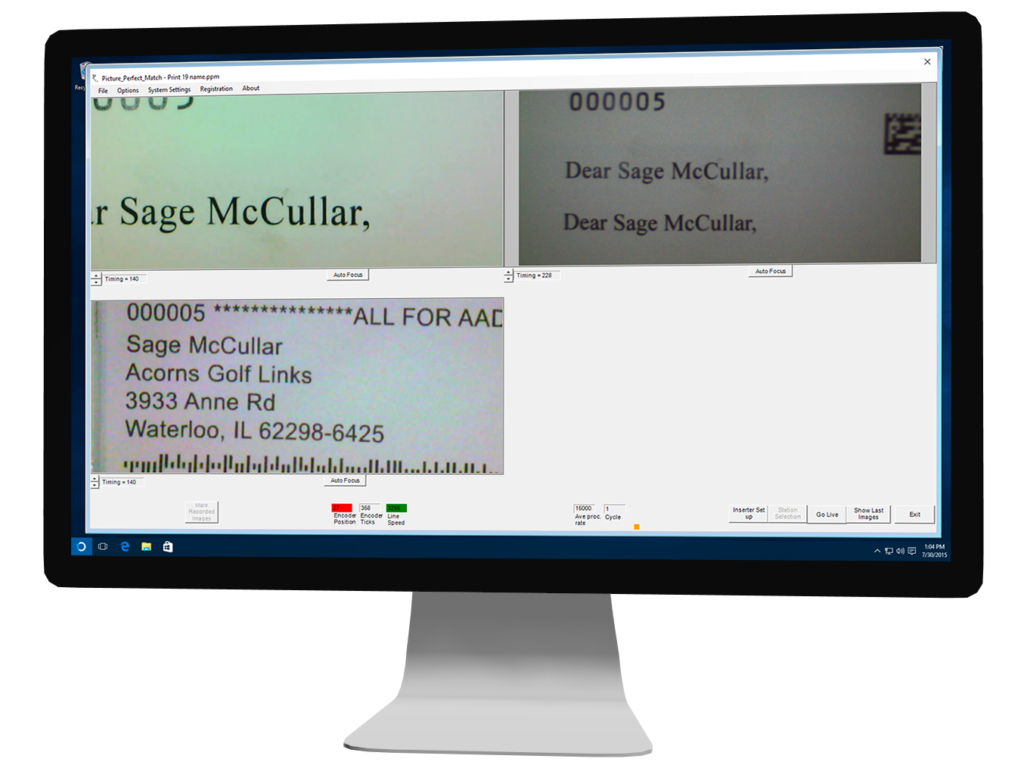

The Run Screen

Picture Perfect stores each image and displays them as frequently as desired. The images remain on the monitor until the next set of images is ready. This means that anytime the operator looks at the screen, a full matched set is there. You can display every piece if needed.

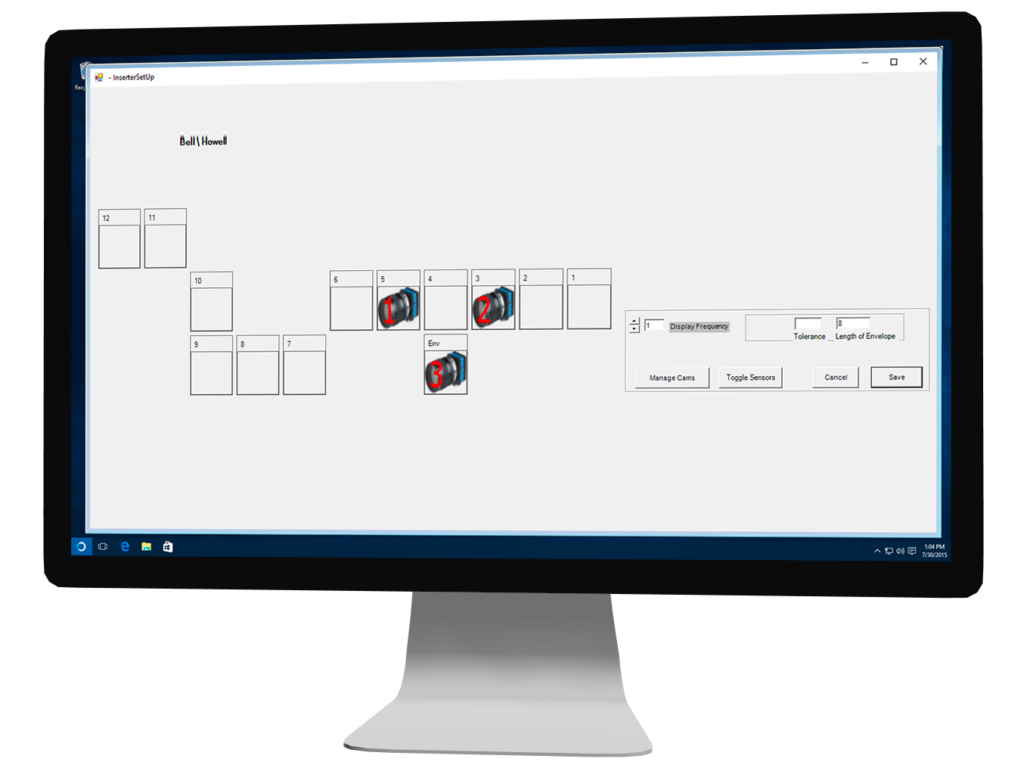

The Set Up Screen

The set up screen is an intuitive graphic interface that can be configured to resemble your machine. Drag the cameras icons that correspond with the locations of the cameras and Picture Perfect automatically determines the correct timing for the cameras.

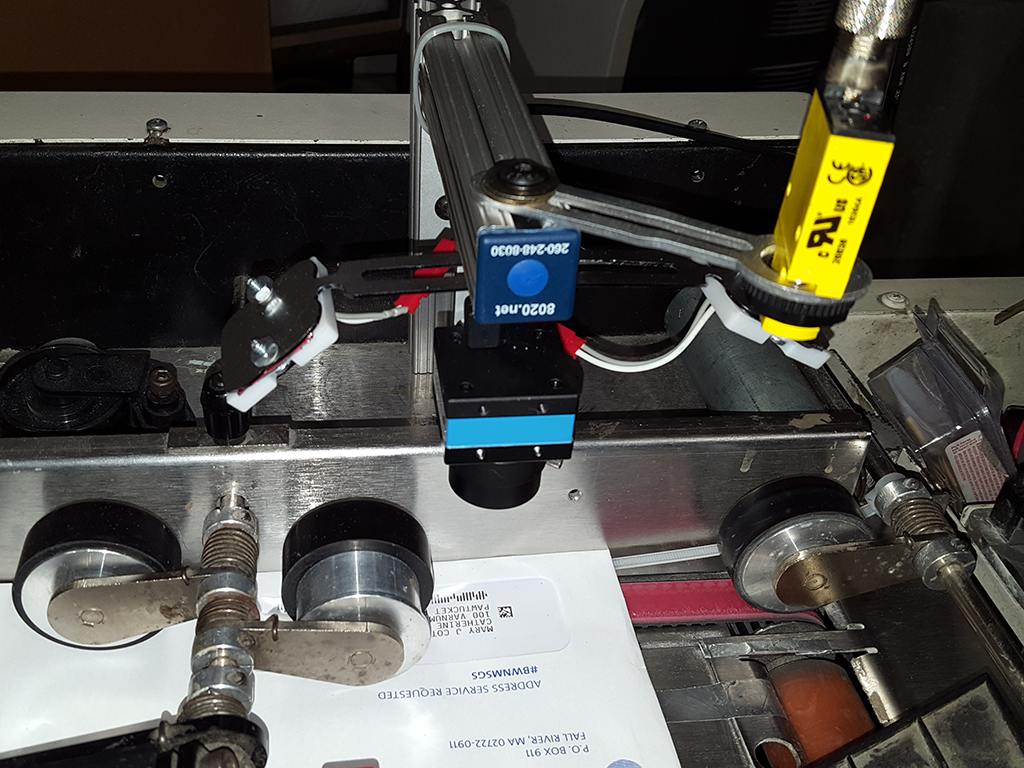

USB Camera Fix Mounted

Cameras can be mounted after the mail piece is inserted for matching or verification.

USB Camera and Flexible Stand

The cameras are USB cameras that are mounted on a flexible stand which is attached to a magnetic base. The power and video use a single cable. The cable is routed through the middle of the stand which provides protection for the cable from moving parts of the machine.

Camera mounted below a Straightshooter.

extend the core system

Powerful add-ons

Automated Systems

The Picture Perfect automated systems, either Optical Character Recognition or Barcode recognition, will monitor your match mailing based on first name, last name, sequence number or account number. Using sequence numbers, sequence checking can be performed during the run. All automated systems will halt the base machine( inserter, stitcher, etc.) on a bad match or sequence check and include end of job Excel report of date, time, data read on the mail piece and whether it was a good or bad match. Automated systems also include End of Process verification which can be set up as a single camera at the end of the machine, as one of the cameras used for matching or as an extra camera while running a match job.

OCR Systems

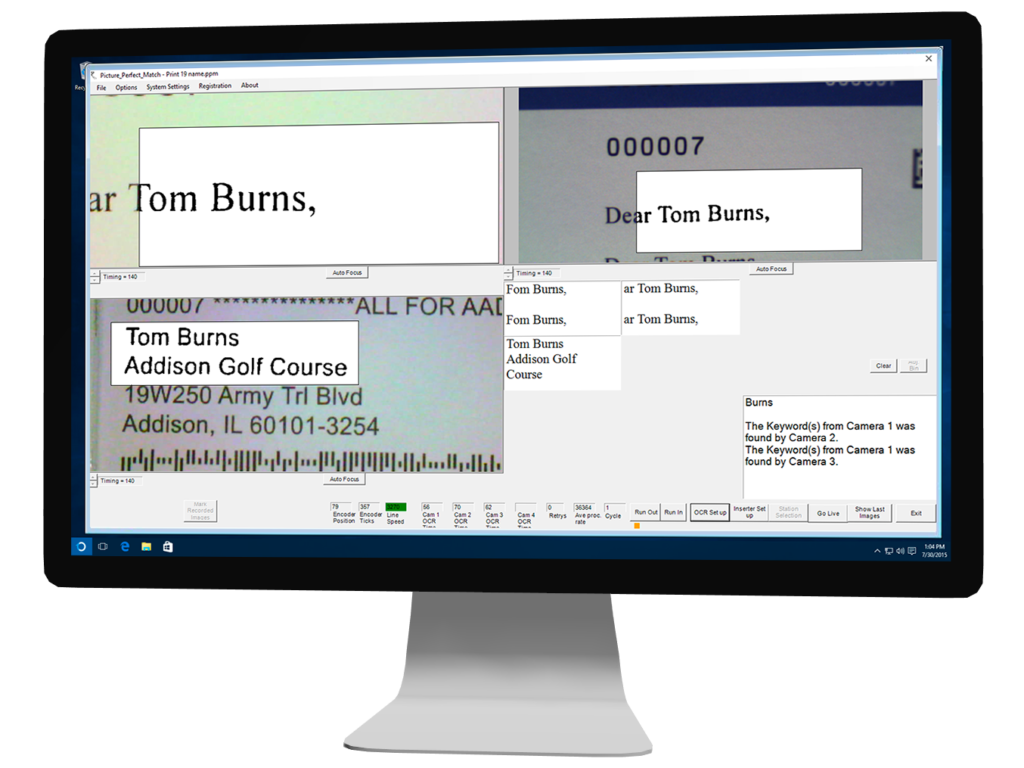

The Optical Character Recognition works by taking the images captured from the cameras of the Picture Perfect Match System and using an OCR engine to look at each pixel of the image, determine if these pixels make up characters and return the characters as text. This text is compared to the text from other image to determine if the mail components match based on parameters set by the user. Because the OCR engine must look at each pixel and its relationship to adjacent pixels, the more text there is to process, the longer it takes to return the results. The PC used to operate this application has the fastest processor available at the time of purchase but there are still some limitations as to how fast an inserter can run using the OCR. Given optimum conditions, the system can operate at 10,000 per hour on a three way match. Some things that affect the speed of the system are: Quality of print, font, font size, lighting, distance and angle of the camera to the area of the mail piece being read, and the camera and mail piece being stationary while the image is taken.

- To match text that is identical on all mail components (i.e. “Dear John” and “John Smith, 123 Main St., Boston, MA 02101.” or “Dear Mr. Smith” and “John Smith, 123 Main St., Boston, MA 02101.”)

- To match sequence numbers that are identical on all mail components.

- To write the results of the OCR to a file.

- To verify that sequence numbers do not skip.

- Set a tolerance of mismatches or sequence number order skips.

- Define whether it is required that the operator perform an action before inserter restart such as press an OK/Ignore button.

The Picture Perfect Match System can perform Optical Character Recognition on the images using the cameras of the basic visual match system and determine within the program whether the components of the mail piece match and output an alert for a mismatch.

The inserter can cycle at 10,000 per hour on a three way match on well printed mail components

A report can be generated with the date, time, results of each mail piece read, good/bad matches, good/bad sequence checking, operator actions.and 2 user defined fields. The report also has a summary with the total run, total good matches. .

The Run Screen

Picture Perfect stores each image and displays them as frequently as desired. The images remain on the monitor until the next set of images is ready. This means that anytime the operator looks at the screen, a full matched set is there. You can display every piece if needed.

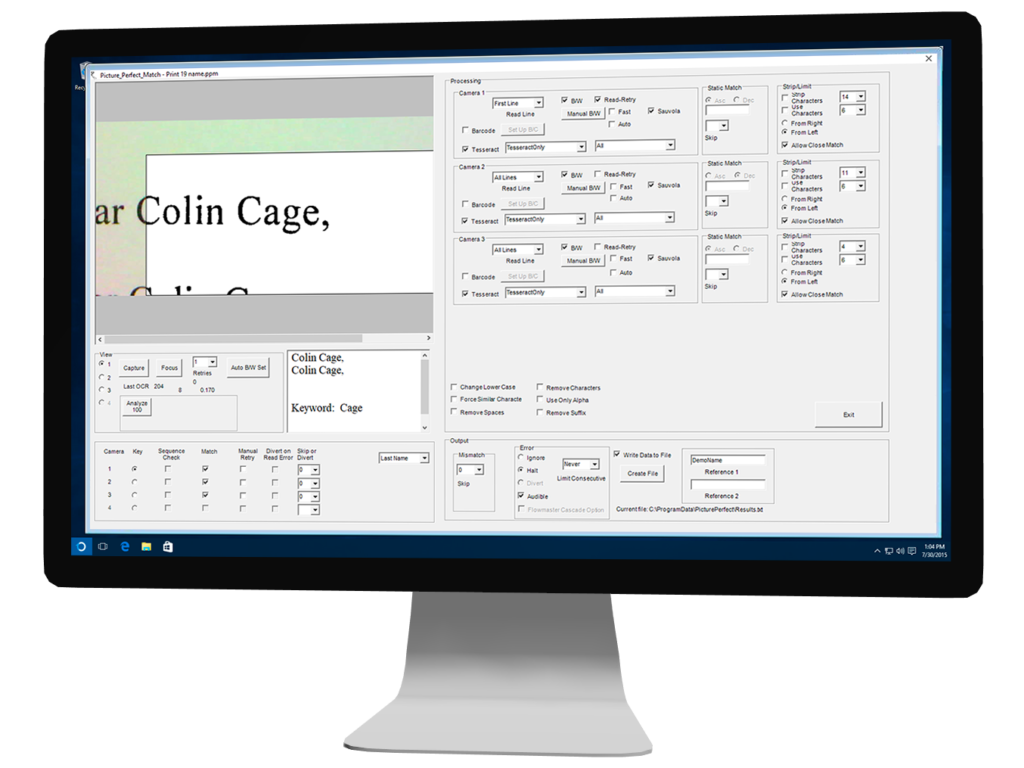

The OCR/Barcode Set Up Screen

The set up screen is an intuitive graphic interface that can be configured to resemble your machine. Press the buttons that correspond with the locations of the cameras and Picture Perfect automatically determines the correct timing for the cameras.

Barcode Systems

The Barcode Recognition Upgrade recognizes IMB, Data Matrix, QR and some 1D barcodes. Information within these barcodes can be compared to a sequence number and written to a file.

A report can be generated with the date, time, results of each mail piece read, good/bad matches, good/bad sequence checking, operator actions.and 2 user defined fields. The report also has a summary with the total run, total good matches.

2D barcode demo at Graph Expo

End of Process Verification

This product, while similar to our original Picture Perfect Match System, utilizes just a single camera located at the end of the process. It provides for a single picture delivered for manual, visual review and quality assurance.

- Great Economical Option or Addition to our original Picture Perfect Match System

- Option to install as Independent System

- Incredible “Low Cost” way to give your clients Quality Assurance

- Any of our upgrades to the original Picture Perfect Match System can be added to this system as well. They provide for great additional quality assurance for your clients.

- Compatible with all available upgrades: Character, Barcode and Image Capture Recognition

- Use as Client Verification

- Not Just for Match Mailing

A report can be generated with the date, time, results of each mail piece read, good/bad matches, good/bad sequence checking, operator actions.and 2 user defined fields. The report also has a summary with the total run,.

System on a swingarm inserter

Picture Perfect End of Machine Verification. One camera reading a barcode and performing sequence checking through a window envelope.

System processing hand work

A demonstration of using a Picture Perfect System for recording the data of a handwork operation. The operator hand feeds pieces under the camera to read a bar code (or OCR) and records the data in the bar code for verification that the piece was finished.

Read & Print

Read bar codes printed on your mail piece, insert them into a blank envelope and print the address inline. This is the most efficient method of matching an envelope to a mail piece.: Picture Perfect’s Read and Print system utilizes one camera to read a barcode from a mail piece and sends the data downstream to the inkjet printer to address the envelope after the inserter exit.Any bad reads can be diverted for hand inspection. Our Read and Print system can be run simultaneously with our matching system.

- One pass operation.

- Inserts do not have to stay in exact order. Mail pieces can be taken from a folder, cutter or laser in batches.

- Missing or damaged mail pieces can be removed before inserting without the need to find the matching envelope.

- Uses HP printing technology.

- Small footprint. The inkjet base is only 16″ wide. Longer bases are available.

Our system uses HP printing technology from inc.jet. Complete read and print systems can be bought through Clear Image Technologies. If you currently have a Jet Engine™ system, we can integrate our reading software to your printer.

Picture Perfect's Read and Print system on a Mailcrafters inserter

Image Capture

In recording mode, every image taken is written to the hard drive in a user specified folder. If a mismatch does occur, the operator can mark these images as "reworked". The images are date/time stamped and can be used for in house quality control or sent to your customer as verification that their mailings were inserted correctly.

- Write Every Image to the Hard Drive

- Mark Mismatched items

- Time Stamp Every Image

- Use as Client Verification

- Not Just for Match Mailing

This feature also allows you to use the system on any inserting job, regardless of whether or not it is a match mailing, as quality control to verify that your customers mail was inserted.